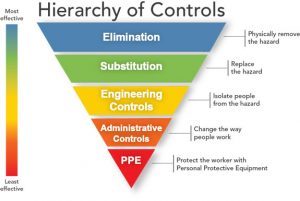

A Control Measure is an action aimed to eliminate a hazard or at least reduce the risk of exposure to an acceptable level. The Hierarchy of Controls prioritizes control measures based on the premise that if the hazard you’ve identified can’t be eliminated then follow the Hierarchy of Controls to select the next-best control to mitigate the risk of an accident, incident, injury, or near-miss in the laboratory. The following guidelines have been adopted from wording found on the “Control Measures” webpage of the American Chemical Society Committee on Chemical Safety.

Elimination and Substitution are considered the most effective control measures. They are easiest to achieve for brand new processes. They can be more difficult to implement for existing processes, because new and/or more expensive equipment and materials may be required.

- Completely get rid of chemicals, materials, processes, and equipment that are unnecessary to your specific experiment. Check if your equipment is well-worn; check dates, and refer to manufacturer’s recommendations.

- Switch out processes, equipment, material, or other components, where applicable. Think about the amount of chemicals or potentially hazardous materials you are using. Can you reduce the amount and still achieve the desired result? Do not use damaged glassware or equipment.

- Some valuable tools to help lab workers determine safer chemical substances are:

You must be logged in to post a comment.